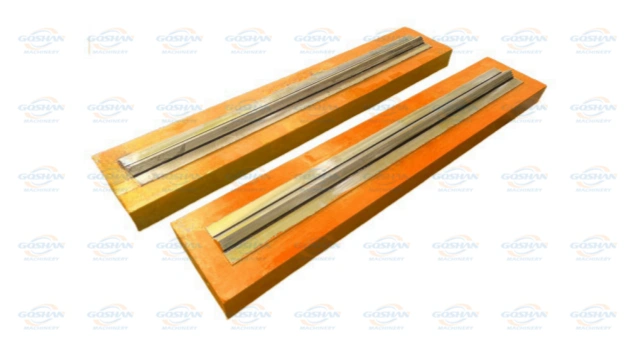

Goshan’s Blow Bar

Our blow bar are available in a variety of sizes, from 200mmx300mm to 800mmx1200mm, to meet various impact crusher models and crushing requirements. In terms of material selection, we offer a variety of high-performance materials, including high manganese steel, medium manganese steel, high chromium cast iron and composite materials. After water toughening, the metallographic structure of high manganese steel is a single austenite, which has high toughness and wear resistance; high chromium cast iron is known for its high hardness and high wear resistance; composite materials have both high hardness and high toughness, with high chromium cast iron on the surface and high manganese steel inside, which perfectly balances hardness and toughness and is suitable for working environments with high impact loads.

We use advanced sand casting or precision casting technology to ensure the shape accuracy and dimensional stability of the hammer. The blanks after casting are finely processed, including milling, drilling, etc., to meet the design requirements. The hardness and toughness of the hammer are further improved through heat treatment processes such as quenching and tempering. After water toughening treatment, the hardness is guaranteed to be 55~65HRC, and the impact toughness reaches 30~35J/cm2, ensuring that the board hammer can maintain excellent performance even in high-intensity working environments.

In order to ensure the quality of the board hammer, we conduct strict dimensional inspection, hardness test and non-destructive testing on each board hammer. Color flaw detection technology can detect surface and near-surface defects such as cracks, pores, inclusions, etc., discover potential problems in time, and ensure the quality and reliability of the board hammer.

.png)